Oak Demilune

Rough cuts

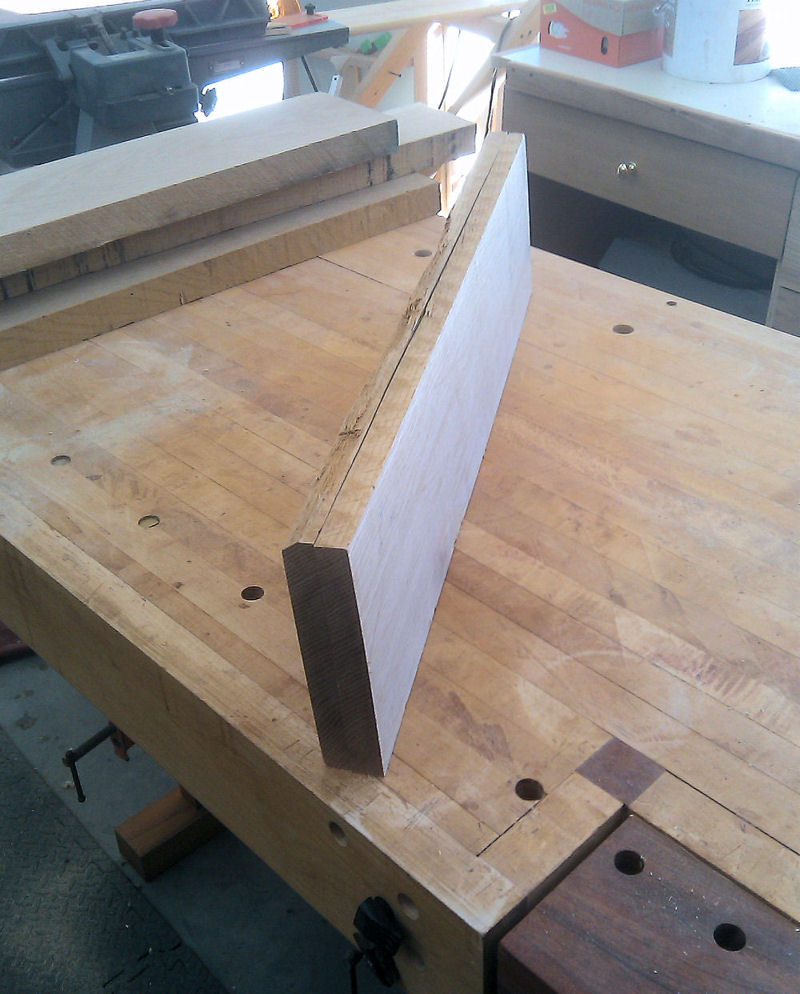

First we need a form to create the curved apron. The form is built up from mulitple layers.

Here you can better see the layers of the bending form.

Now we cut a thin strip off of the 2" thick oak plank.

Here you can see the thin strip. I continually reduce the thickness of this sample piece to find what thickness will bend around the form without breaking. Ultimately, multiple strips are bent around the form and glued into a solid bent apron.

The test strip is now thin enough to be bent around the form. Thus, I can begin to cut the rest of the strips to this thickness (plus a small amount to allow for sanding and planing each strip smooth).

Another view of the clamping process. Only one side is clamped here. More on the laminations of the apron below.

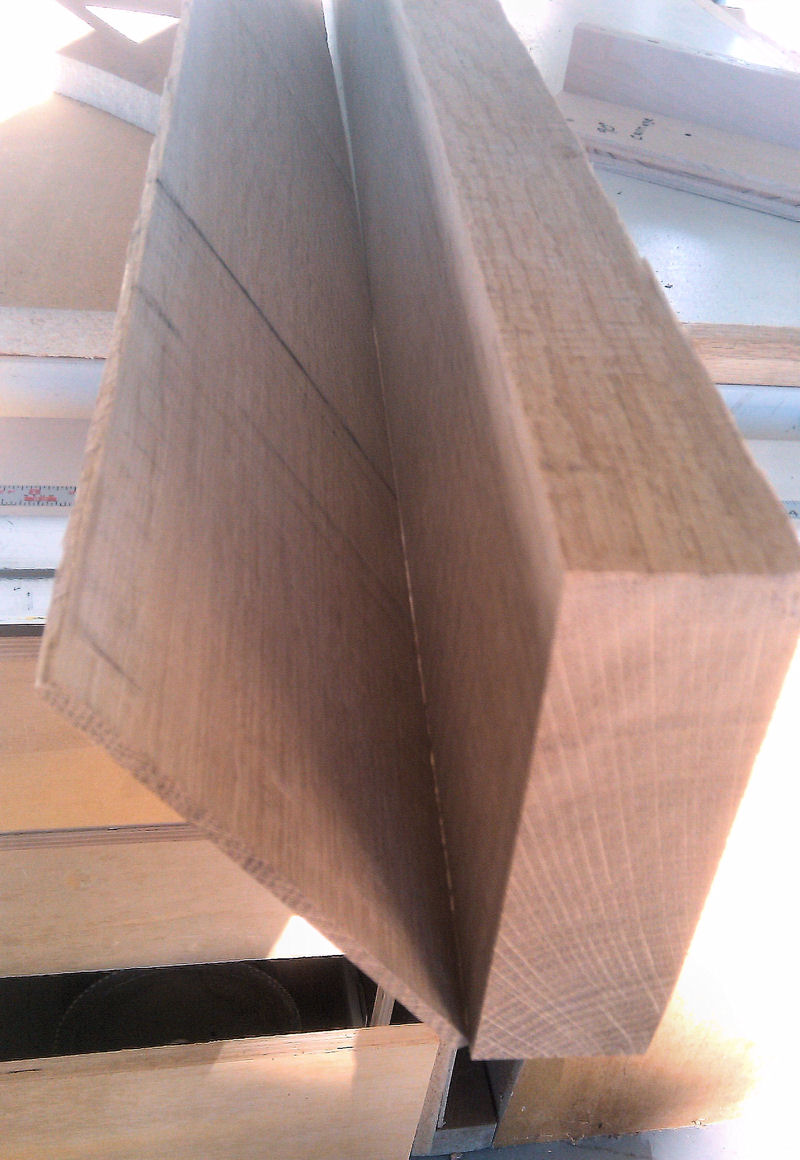

Here's the plank that will form the top. A 2" inch thick plank will be split lengthwise to create a matched set for the top.

A terrible picture of the beginning of the splitting, or re-saw, process on the bandsaw.

For safety, the board is fed through the saw using an old Jedi mind trick rather than human hands.

Here's the board post-resaw.

And when opened up, voila! Perfectly bookmatched panels. The panels will be trimmed and glued up into a single top plank.

Edges trimmed, the two sides are ready to be glued up.